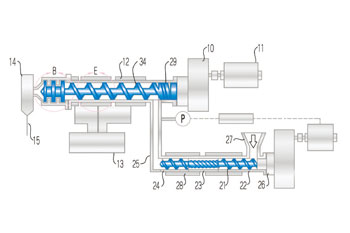

Tandem extruders mean that whole extrusion will be composed of two extruders. The first extruder will finish melting or plasticizing process and discharge the melts into the sequential extruder. The second extruder will finish extrusion process and pump the melt through die. The aim of such system is to reach high output capacity under controllable melt temperature. Most of such extruders are used for the large scale production.

How to Operate tandem extruders?

The tandem extruders can be operated as the normal single screw extruders with the close-loop controlling system between the two extruders. There will be one pressure transducer located in the adaptor between the two extruders and with the pressure signal the 2nd extruder will run at certain screw speed completely automatically. What we need to do is to regulate the screw speed of the 1st extruder according to the line requirements.

Technical Parameter

|

Type |

1st Extruder |

2nd Extruder |

L/D |

Screw Speed (rpm) |

Capacity (kg/h) |

|

SJK45/SJ65 |

SJK45 |

SJ65 |

28-22 |

350,55/90,18.5 |

150-200 |

|

SJK65/SJ90 |

SJK65 |

SJ90 |

28-22 |

250,90/90,45 |

300-500 |

|

SJK90/SJ120 |

SJK90 |

SJ120 |

28-22 |

180,220/90,110 |

600-1000 |

|

SJK120/SJ150 |

SJK120 |

SJ150 |

28-22 |

150,315/90,132 |

800-1600 |

|

SJK150/SJ180 |

SJK150 |

SJ180 |

28-22 |

120,500/80,220 |

1800-3000 |

Related Keywords: purchase tandem screw extruders for elongation and plastic processing, tandem extruder manufacturers Asia/China, tandem extrusion machines China